Introduction

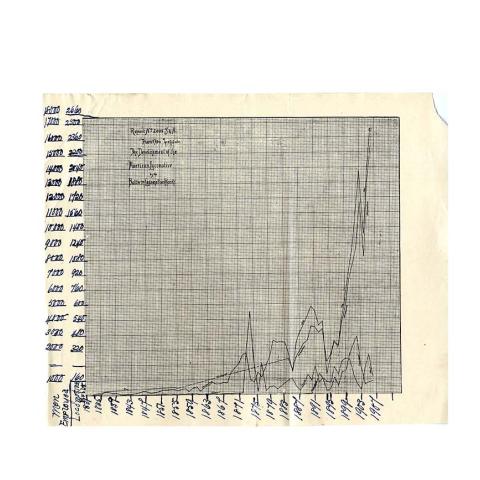

First an apprentice in the trade of jewelry making, Matthias Baldwin's mechanical tinkerings eventually led him to designing and experimenting with locomotive improvements. By 1837, his Baldwin Locomotive Works employed three hundred skilled artisans and produced forty locomotives annually. The company flourished as the U.S. railroad system expanded.

Why did Baldwin move from jewelry making into large-scale locomotive production? And how did the changing economy of the 1800s impact the Baldwin Locomotive Works?

An Unschooled Tinkerer

Matthias Baldwin, born in 1795, was an unschooled tinkerer with all things mechanical. His mother apprenticed him to Philadelphia jewelmakers at the age of 16. After learning the trade and operating his own business, first in jewelry and then widening into other areas of tool work, Baldwin went into business with a machinist and woodworker named Mason. The combination of their talents resulted in machinery products for the printing and binding industry.

Item of Interest

The company's success led to a need for an energy source beyond the horse and hand-driven systems being used, and so one of the newly-available steam engines was acquired. The new engine was not completely acceptable and Baldwin began to improve it but eventually replaced it with one of his own invention. Upon learning of this skill, a local museum owner asked Baldwin to build a model version of a steam locomotive. At that time, this was an item of high interest following news of its 1825 invention by Stephenson in England and the "Rocket's" success in the August 1829 Rainhill trials. No one Baldwin knew had ever actually seen a full-size steam locomotive, although a few were being imported privately.

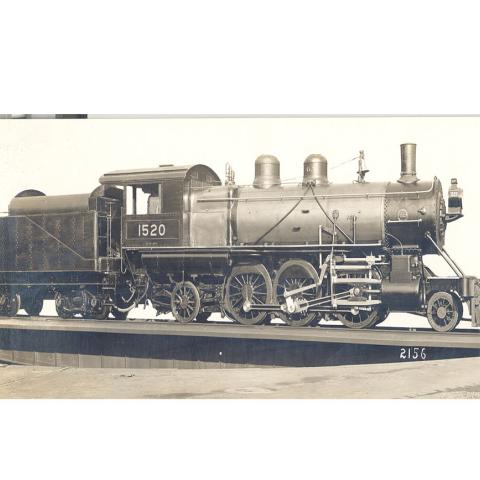

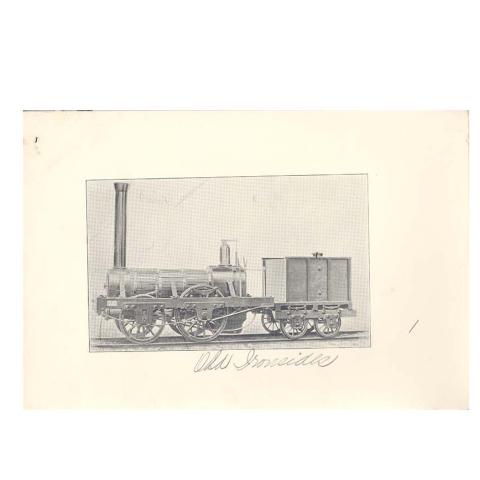

Old Ironsides

At that time, the railroads in the entire United States amounted to around 250 miles of wooden track with cars that were pulled along the track by horse teams. Transportation was mainly by horses on toll roads and water-borne transit became available with the opening of the Erie Canal in 1825. Steam trains would be the next development in linking the United States countrywide.

In the museum display in 1831, Baldwin's model locomotive pulled cars with four passengers around a circular track. The popularity of this display prompted a local railroad company to order a full-scale version. Fortunately, Baldwin was able to look at one of the scarce imports before building his own version. Baldwin moved his assembly shop to larger premises close to Philadelphia city limits, jobbed out the manufacture of larger parts he could not handle, and within six months, assembled the wood and iron locomotive known as "Old Ironsides." Its successful test run took place on November 23, 1832; weighing six tons, it pulled 30 tons at 28 miles per hour on a level surface.

There were some technical drawbacks in "Old Ironsides" that displeased the owners and temporarily discouraged Baldwin's manufacturing progress. Despite the drawbacks, he continued experimenting and designing locomotive improvements and doing sundry machine work, as well as maintaining his business in stationary steam engines. His partner, Mason, had departed in 1829, unconvinced of the promise in the new endeavors.

Large-Scale Production

In 1833, Baldwin visited the Mohawk and Hudson Rail Road to examine a recently acquired Stephenson locomotive and realized he could make a better version. He did so with a model he sold in February, 1834, at the same time obtaining a U.S. patent for its "half crank" feature. Now each locomotive produced by the Baldwin Locomotive Works improved progressively and their manufacture became its central aim. By 1837, the company employed three hundred skilled artisans and produced forty locomotives annually.

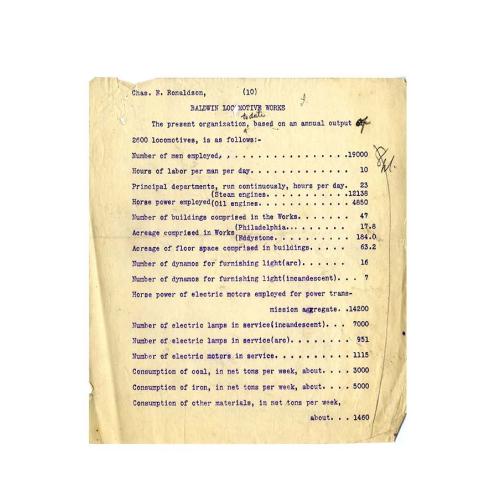

The Works' progress moved in tandem with burgeoning U.S. railroad expansion. All aspects of a large manufacturing plant were being invented as required: the logistics of fuel and raw materials supply from the coal and iron mines of Pennsylvania to the supply or manufacture of suitable tools, both hand and machine. The processes of large-scale industrial production were being discovered and established at the company, which would be the largest locomotive manufacturer in the world.

Holding It Together

During and following the financial Panic of 1837, Baldwin held his company together through frank negotiations with creditors and a series of partnership arrangements that brought needed funds while freeing Matthias Baldwin to concentrate on design. The result was a further patented innovation—the flexible-beam design which improved stability and hauling power.

Still, the locomotive industry languished through the early 1840s, mirroring the state of national commerce. In the latter 1840s railroading built rapidly with increasing line operators, increasing line builders and a matching increase in the number of engine manufacturers from New Jersey to Massachusetts, expanding competition for the Baldwin Locomotive Works. Lacking an industrial loan system, it was left to the creativity of each operator to find their best financial arrangements in this highly competitive atmosphere and Baldwin struck many deals with suppliers (a Baldwin locomotive contained over 4,000 parts) and customers (a thirty-day performance guarantee) to stay solvent and operational. The early start in the business served Baldwin well and by 1846 the product line included fifteen different engine sizes or types.

Industrial Organization

During this time, the owners of the Baldwin Locomotive Works were learning and inventing the principles of factory management in one of the earliest examples of integrated industrial organization. There were about four hundred workers, craftsmen, and general laborers, supervised by foremen who were in turn responsible to a trio of company owner/managers. The divisions of the factory included machine shops, boiler and smith shops, a foundry, and a paint shop. The new factory model replaced the earlier craft-based system and its family workers with a group of unrelated wage earners brought together for the single manufacturing purpose.

Booming railroad expansion caused increased competitors in Baldwin's field and railroads now exploited this choice of suppliers by introducing competitive bidding and sourced locomotive designs rather than those of the manufacturer. To combat manufacturing inefficiency, Baldwin aimed for cost control and an assured capital base with major changes. They managed labor costs by instituting piece work and streamlined processes by dropping the manufacture of stand-alone steam engines and standardizing the parts used in locomotive assembly.

Using Baldwin's superior experience and data to expand model choices, the company flourished through the 1850s and by 1857, six hundred employees produced sixty-six locomotives. Then suddenly, in August, the financial Panic of 1857 hit, causing multiple failures in the overextended railroad business and locomotive orders plummeted. The recession following this crisis lasted a number of years during which Baldwin laid off workers, leading to the formation of a worker's union and an 1860 strike by skilled workers. In response, Baldwin maintained production with apprentices and replacement hires and spread salesmen far afield to obtain orders. The unionization of the Baldwin Works failed and never resumed.

Loss and Gain

The company, now stabilized and financially secure, encountered mixed outcomes during the American Civil War. The loss of customers in the southern states was countered by orders from the military and from the Pennsylvania Railroad in response to the boosted traffic on its routes across the northern states. The wartime economy and its accompanying inflation and increased orders allowed Baldwin to assert its financial soundness with cancellation of credit arrangements and establishment of billings on a cost plus, rather than fixed price, basis.

In the year after the war's end, September, 1866, Matthias Baldwin died, leaving the company sound in management practices and technical prowess.

A Superior Company

As an industry pioneer, the superior experience of the Baldwin Works gave it flexibility and adaptability during the erratic period following the war. Its Philadelphia location gave major benefits with ready access to financial operators, a skilled labor pool, a close relationship with the Pennsylvania Railroad and proximity to the lines hauling coal—the lifeblood of this Second Industrial Revolution—from the state's mining areas. Baldwin became the primary locomotive producer during the Gilded Age of fortune-making. Competitors fell away as the economy see-sawed through the economic uncertainties and panics of 1873, 1893, and 1907.

At the turn of the century, the railroads were booming, mechanical design had improved greatly, and moves were afoot in the locomotive industry to form cartels which would co-operate in an effort to combat uncertainties in the industry and, not coincidentally, to fix prices. Baldwin did not join these groups. They eventually failed, unable to realize the economies of scale in a constantly changing market.

In 1906, its banner year, Baldwin produced 2,666 engines, working around the clock with seventeen thousand shift workers. This performance prompted the construction of a new satellite plant in Eddystone, 15 miles from downtown Philadelphia, to handle the anticipated extra work. Baldwin's timing was bad, however, as this move coincided with the beginning of the steam train's decline.

Interested in learning more about Baldwin Locomotive Works? Learn More About Their Cresson Award

Breakdown:

After the financial Panic of 1907, with the Interstate Commerce Commission regulating the rates to be charged, railroad profits and spending on equipment declined even as rail traffic reached record levels. Baldwin incorporated in 1909, then made an initial public stock offering in 1911 in efforts to raise funds to pay for the Eddystone plant and maintain operations, but was still forced to reduce wages and lay off many workers.

In 1910, the good relations between management and workers broke down. Police reaction to a strike by Philadelphia transportation workers ballooned into a confrontation with Baldwin workers and eventually into a general strike by workers across the city. Union organizing was set in motion at Baldwin Locomotive Works, resulting in establishment of thirteen separate, but cooperating, craft unions. No lasting agreement was reached between the unions and the managers on matters of overtime wages, rehiring procedures, and working conditions, and a strike was called in June of 1911. The strike lasted a few weeks before breaking down and operations at Baldwin resumed on a less cordial basis.

Baldwin managers failed to recognize or adapt to changing circumstances as the age of steam engines waned. They began a diversification program in 1929 just as the Great Depression began. The company was overextended, sales of capital goods evaporated, and Baldwin Locomotive Works filed for bankruptcy in 1935.

Innovation Required

As Baldwin set out to build the first U.S. steam locomotive, the range of complexities they would encounter could not have been foreseen. Building a machine for the conversion of fuel energy, mostly coal, to mechanical transport energy required innovation at every single step of the way. In the beginning, the materials available were elemental metals, such as iron and copper, and wood. The tools necessary for high precision engine parts were scarce and unsuitable for mass manufacturing. So even the tools to make the parts—to make the locomotives—had to be invented first.

A Complex Process

Steam, the propellant for the locomotive engine, is produced in a container (boiler) through which flue gas tubes have been inserted. Hot gases from burning coal passing through the tubes, the heat is transferred to the water in the boiler, converting it to steam. This steam is then superheated by recirculation across a further set of boiler tubes and the resulting steam is fed into engine cylinders to operate pistons. Slide bars, connecting the engine pistons to the wheel connection rods, convert the reciprocating (linear) thrust of the pistons to the rotary motion of the train's driving wheels.

The complexity of the locomotive requires a wide variety of scientific factors—material, structural, and operational—to be taken into account.

Early locomotives contained wood used for wheel parts and framing and iron (both cast and wrought) for the boiler, chimney, drive connectors, and wheel rims. Flue tubes were made from copper using that metal's superior heat transfer capability. Other materials, such as brass, were tried but failed the durability test. Old Ironsides was the appropriate name of Baldwin's first locomotive. After the invention of the Bessemer process in the mid-1850s, steel replaced the iron and wood.

Classification

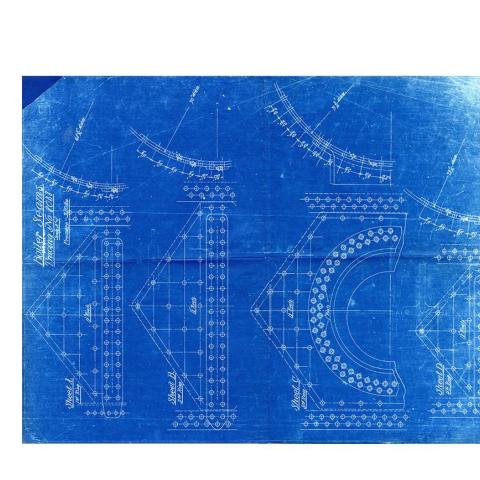

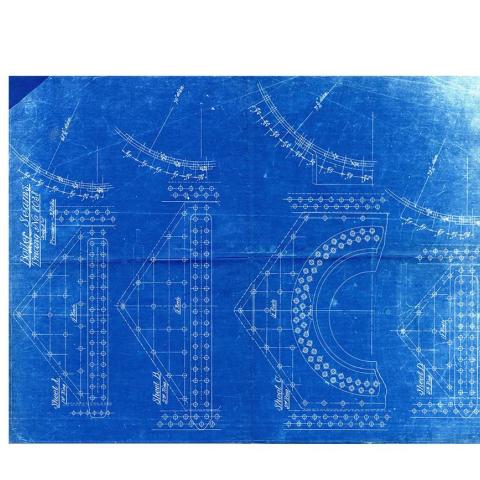

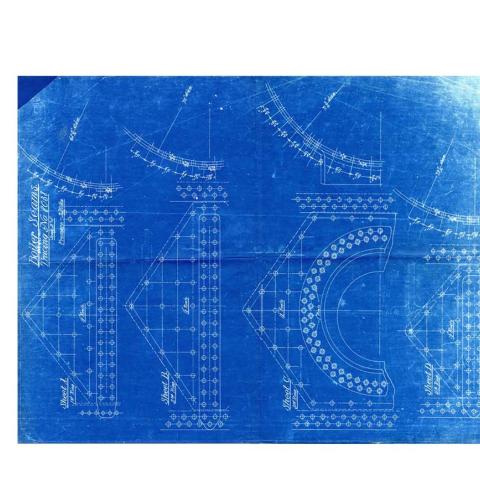

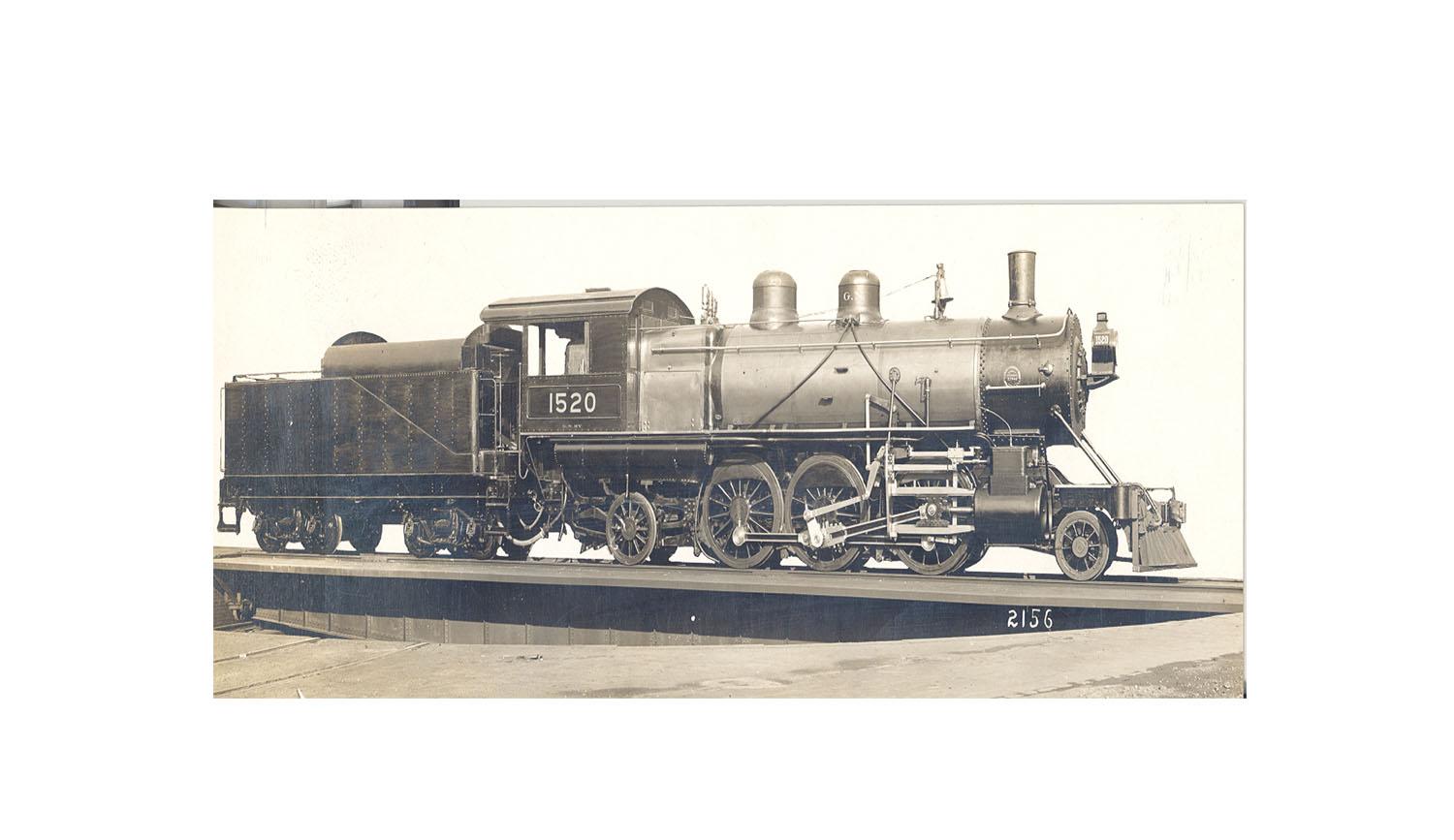

Old Ironsides was a four-wheeled locomotive with the two rear wheels being the driving wheels. The next engine Baldwin built had six wheels: the front two non-driving wheels being replaced by a four-wheel swiveling "bogie" car which improved traction and weight distribution on the track. By ten years later, Baldwin had created an engine, the six-wheels-connected locomotive, which answered the questions of increased power, weight distribution, and traction on curves. All six wheels were drivers: the rear two fixed and the front four drive-connected yet assembled to operate as separate pairs in negotiating curves.

As the wheel arrangements of locomotives grew, a system of classification was established. Three sets of numbers, in the format NN-NN-NN, described the type and combination of wheels. The first NN value shows the number of guide wheels in front of the larger driver wheels, the second value the number of driver wheels, and the third the number of guide wheels behind the driver wheels. Old Ironsides' classification was 0-4-0.

Standardization

Engine designs were under constant development and patents awarded multiplied with improvements to drive train assemblies, firebox and fuel efficiencies, and fabricating techniques. The construction of tight boiler joints and seals was particularly important. Baldwin's introduction of ground joints for steam pipes permitted increase of boiler pressure from 60 psi to 120 psi with corresponding improvement in thermodynamic efficiency. Other patented advances included an equalizer to distribute shocks from rough rails and keep the train on the tracks, an arrester to prevent dangerous sparks from leaving the smokestack, and a draft maker to improve fuel burning quality.

In 1892, rules were set by Purdue University for scientific testing of locomotive performance. The areas covered were traction power measurement, furnace conditions, and fuel and water analysis. New, formal design standards simplified and replaced the previous "try it and see" approach used previously.

While it took skill and ingenuity to build locomotives, equal qualities were required of those who operated them. With few automated controls available, the operating team had to ensure that the raw material, water and coal, supply was exactly right and that the driving steam energy was properly applied and controlled so that the team of man and machine could function well.

Maximum Power

Structural considerations in building locomotives ranged from the finest detail to the largest feature. American railroad tracks were made of light iron and wood with more curves and inclines than their British counterparts so designs were revised to improve traction and maneuverability. The main goal was to get maximum power to the wheels, driving the locomotive at the highest speed and avoiding derailment and excessive track wear or damage. The risk of explosion and fire also had to be taken into account.

Such varied conditions precluded standardization!

Credits

The Baldwin Locomotive Works presentation is made possible by support from The Barra Foundation and Unisys.

This website is the effort of an in-house special project team at The Franklin Institute, working under the direction of Carol Parssinen, Senior Vice-President for the Center for Innovation in Science Learning, and Bo Hammer, Vice-President for The Franklin Center.

Special project team members from the Educational Technology department are:

Karen Elinich, Barbara Holberg, Margaret Ennis and Zach Williams.

Special project team member from the Curatorial department: John Alviti.

The project's Advisory Board Members are:

Ruth Schwartz-Cowan, Leonard Rosenfeld, Nathan Ensmenger, and Susan Yoon.

Read the Committee on Science and the Arts Report on Baldwin Locomotive Works and their recommendation for the Cresson Medal.